BELZONA REFURBISHES 128 STAINLESS STEEL PIPE FLANGES

Industry: Power (POWR)

Application: VPF-Valves, Pipes and Fittings (VPF)

Substrate: Stainless steel

Customer Location: Nuclear Power Plant in New York

Application Date: January 1996

Products:

Belzona® 1111 (Super Metal)

Problem: The 3" diameter stainless steel piping suffered from micro biologically induced corrosion (MIC) and corrosion from brackish water.

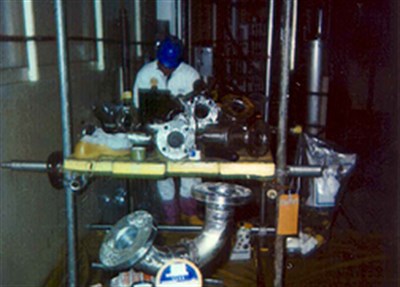

Photograph Descriptions

- Part of the service water system containing the stainless steel piping

- Some of the 3" diameter stainless steel spools being prepared

- Former being used to apply uniform thickness of Belzona® 1111 to the corroded flange faces

Application Situation

Emergency service water system, (cooling water to containment air coolers)

Application Method

Application was carried out in accordance with Belzona Know-How Leaflet VPF-13. Formers treated with Belzona® 9411 were used to form Belzona® 1111 to a thickness of 0.128" on each flange face to allow for leak free assembly.

Belzona Facts

Replacement of the system at a cost of $270,000 was considered but the Belzona alternative, which cost $7,000, was chosen and design basis accident (DBA) testing provided the customer with a repair product which eliminated the expense of welding in new flanges which would have taken three weeks as opposed to the four days taken with the Belzona repair.