I.D. FAN SHAFT REPAIRED IN SITU WITH BELZONA

Industry: Power (POWR)

Application: MPT-Mechanical Power Transmission (MPT)

Substrate: Steel

Customer Location: Power plant, Bulgaria

Application Date: May 2006

Products:

Belzona® 1111 (Super Metal)

Problem: Shaft damaged at bearing location by seized bearing.

Photograph Descriptions

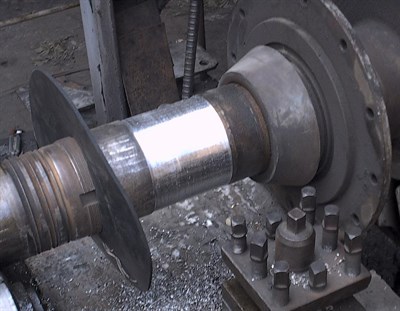

- Damaged area of the shaft undercut

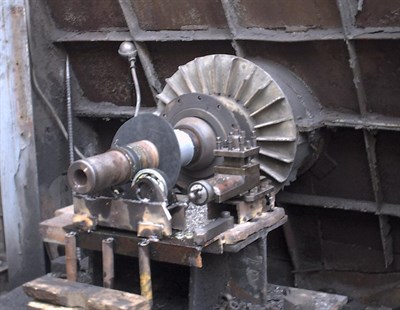

- All machining and application work carried out on site by using fan rotation and small hand lathe

- Belzona® 1111 applied

- Machining to the final diameter

Application Situation

Shaft of induced draft fan.

Application Method

Application was carried out in accordance with Belzona Know-How System Leaflet MPT-1. The journal was prepared and machined in situ using the draft of the gases to rotate the shaft. Simple small lathe was mounted to machine the area to desired diameter.

Belzona Facts

Belzona used to rebuild the original dimensions of the shaft without dismatling the fan. Belzona returned the equipment in service with minimal production down time. This procedure has become standard for emergency shaft repairs in the plant.