BELZONA RESTORES STEEL MILL FLUME

KHIA ID: 1129Industry: General Industry (GIND)

Application: TCC-Tanks and Chemical Containment Areas (TCC)

Substrate: ConcreteCustomer Location: Steel Mill, USA

Application Date: December 2007Products:Belzona® 4124 (Bulk Fill)Belzona® 4111 (Magma Quartz)Belzona® 1812 (Ceramic Carbide FP)

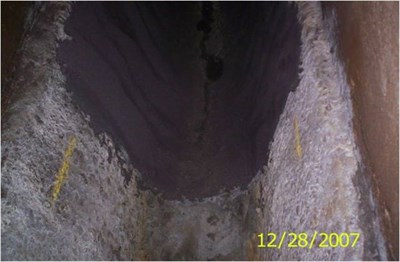

Problem: Highly abrasive waste material was rapidly eroding the flume, carving out a larger cross-sectional area than original designed. Flow velocity dropped as a result and the flume was not longer functioning as designed thus allowing build up of waste within the flume.

Photograph Descriptions

- Trough prior to surface preparation

- Trough profile reformed with Belzona

- A further quarter inch of Belzona® 4111 applied

- Trough fully coated with Belzona® 1812