BELZONA DOUBLES PUMP SERVICE LIFE

Industry: Chemical & Petrochemical (PETR)

Application: CEP-Centrifugal Pumps (CEP)

Substrate: Cast Iron

Customer Location: Petrochemical Plant, Ukraine

Application Date: December 1999

Products:

Belzona 1311 (Ceramic R-Metal)

Belzona 1391 (Ceramic HT)

Problem: Due to crystallization of paraffin erosion-corrosion damage occurred on the case of the pump and cover. Acquisition of certain parts of the pump was not possible.

Photograph Descriptions

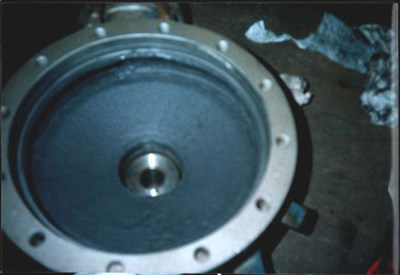

- Grit blasted casing

- Pump cover before rebuilding

- Belzona® 1311 applied to casing

- Completed application

Application Situation

Centrifugal pump used for mixture of paraffin and petrolatum between -30°C and +30°C. Due to the build-up of product, the system is washed once a day with a mixture of MEK and Toluene at 80°C.

Application Method

The application was carried out in accordance with Belzona Know-How System Leaflets CEP-5 and -3. areas were rebuilt using forming techniques.

Belzona Facts

Repair was done within 8 hours. In 3 days the pump was returned to service. Using Belzona allowed the customer avoid having to purchase new pump parts. this application increased average service life of such pumps from 4368 hours to 9168 hours.