BELZONA SEALS TRANSFORMER BUNDING

KHIA ID: 1706Industry: Power (POWR)

Application: GSS-Gaskets, Seals and Shims (GSS)

Substrate: Concrete and polyethyleneCustomer Location: Electrical power company, Sweden

Application Date: August 2010Products:Belzona® 4111 (Magma Quartz)

Belzona® 2141 (ACR-Fluid Elastomer)

Problem: The bunding for oil-filled transformers was made up of many interconnected small concrete bunds. Connection to each bund was through polyethylene pipes. These pipe penetrations were sealed with rubber sleeves. The outer walls had polyurethane foam inserts. The glands and end-plugs were leaking since the concrete bunds were moving independently of each other. There were 32 penetrations in total with 62 sealing points on either side of the penetrations. The power company decided to seal all the pipe penetrations. The 18 end plugs in the outer wall were also replaced with Belzona.

Photograph Descriptions

- Transformer sub-station in central Sweden

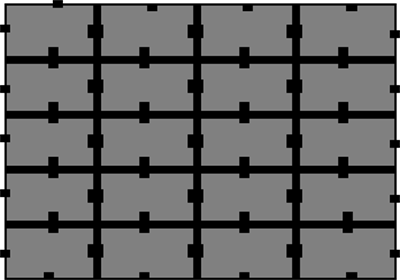

- Diagram of the secondary containment under the transformer. Note the glands and end plugs

- Leaking gland

- All penetrations were sealed with Belzona® 2141