BELZONA REPAIRS FAN AT PULP AND PAPER MILL

KHIA ID: 235Industry: Pulp & Paper (PLPR)

Application: FBC-Fans, Blowers and Compressors (FBC)

Substrate: Mild SteelCustomer Location: Pulp and paper mill - South Africa

Application Date: March 2001Products:Belzona® 1391

Belzona® 6111 (Liquid Anode)

Belzona® 5111 (Ceramic Cladding)

Problem: Magnesium Oxide fan and casing were being destroyed by a serious corrosion/erosion cycle. The process temperature was 150-165C. Although the process is dry, moist air was being sucked in through the shaft hole, corroding the steel.

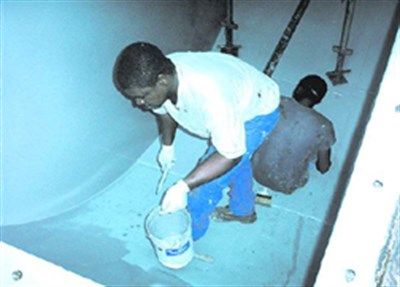

Photograph Descriptions

- The fan has been grit blasted and is ready to be coated

- The top of the fan casing has been coated with Belzona® 6111 (Liquid Anode)

- Belzona® 5111 (Ceramic Cladding) is being applied to the fan casing bottom