BELZONA PERFORMANCE IMPROVEMENT PROGRAM (PIP) CUTS RUNNING COSTS DRAMATICALLY

Industry: Water / Wastewater (WATR)

Application: CEP-Centrifugal Pumps (CEP)

Substrate: Cast iron / Bronze

Customer Location: Potable Water Supply Company

Application Date: March 1995

Products:

Belzona® 1111 (Super Metal)

Belzona® 1341 (Supermetalglide)

Problem: Reduced flow and pressure coupled with motor overheating

Photograph Descriptions

- Deteriorated pump components

- Performance improvement information

- The completed application following refurbishment

Application Situation

Submersible potable water booster pump

Application Method

The application was carried out in accordance with Belzona P.I.P. computer generated engineering specification from detailed information supplied by the end user.

Belzona Facts

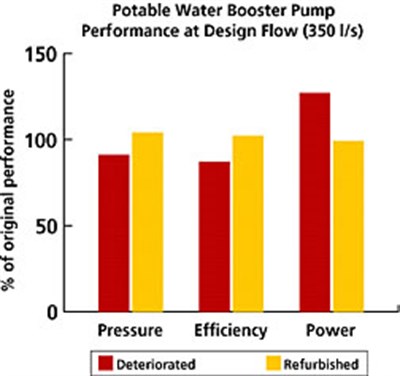

The pump unit was identified for potential overhaul while still in service due to reduced output and overheating of the drive motor, a characteristic of reduced hydraulic performance. When the unit was removed and disassembled for inspection, considerable erosion had occurred on the diffuser bowls, which were also badly deteriorated from the effects of nodal growth and corrosion. By utilizing Belzona computer generated overhaul techniques specific to this pump type and its operating conditions, substantial savings in running costs - approximately $55,000/year, coupled with sustained high levels of performance, increased output and long term protection were achieved.