BELZONA RESTORES CHIPPER DISC POCKETS TO LIKE NEW CONDITION

KHIA ID: 306Industry: Pulp & Paper (PLPR)

Application: SHM-Solids Handling Machinery (SHM)

Substrate: SteelCustomer Location: Pulp and paper mill in Washington, USA

Application Date: Winter 2000Products:Belzona® 1311 (Super R-Metal)

Belzona® 1321 (Ceramic S-Metal)

Problem: These chipper disc pockets are worn from continuous wood abrasion and eventually were unable to produce satisfactory chips.

Photograph Descriptions

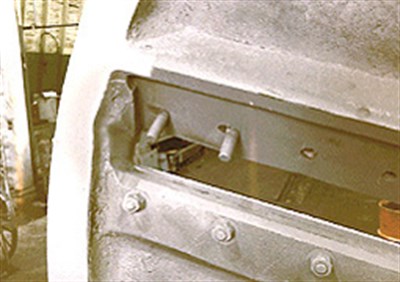

- Significant metal loss on the exit side of the pocket

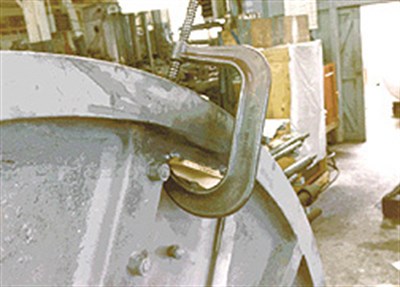

- Knives C-clamped into the wet Belzona

- Two coats of Belzona® 1321 for a finished smooth surface