BELZONA RECLAIMS A SHAFT AFTER A BEARING FAILURE DAMAGED BOTH ENDS

KHIA ID: 309Industry: Pulp & Paper (PLPR)

Application: MPT-Mechanical Power Transmission (MPT)

Substrate: SteelCustomer Location: Abitibi Price Paper Mill in Ontario, Canada

Application Date: 1988Products:Belzona® 1111 (Super Metal)

Problem: A hydraulic press on either end of an embossing roller is used to control appropriate operating pressure, caused premature bearing failure, damaging both ends of the shaft.

Photograph Descriptions

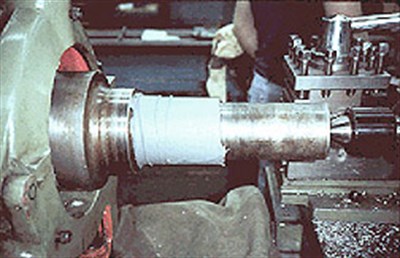

- Scored shaft of an embossing roller

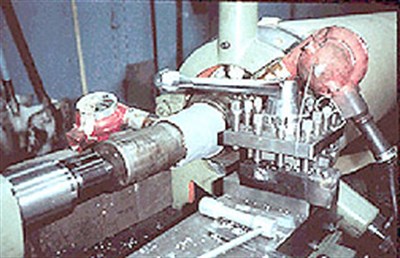

- Application of Belzona® 1111 (Super Metal)

- Accelerating the cure using a heat gun

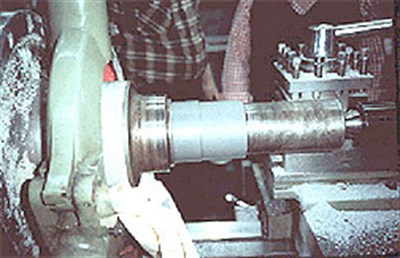

- Rebuilt bearing surface and shoulder using lathe