BELZONA REPAIRS SHAFT QUICKLY AND EFFECTIVELY

KHIA ID: 3123Industry: Steel & Metal Processing (STEL)

Application: MPT-Mechanical Power Transmission (MPT)

Substrate: Mild steelCustomer Location: Aluminium producer, Brazil

Application Date: June 2011Products:Belzona 1111 (Super Metal)

Problem: Lubrication failed and the bearing wore the shaft creating vibration. The equipment had to be stopped and the shaft repaired.

Photograph Descriptions

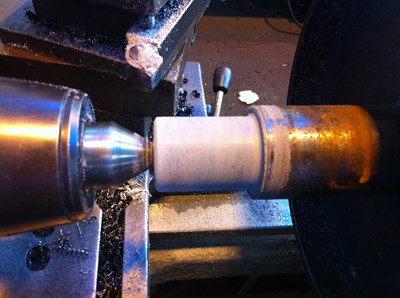

- The roller mounted in the lathe

- The damaged shaft end

- Shaft prepared by rough machining

- Belzona 1111 machined back to required diameter