BELZONA REPAIRS CONVEYOR BELT WITH MINIMAL DOWNTIME

KHIA ID: 314Industry: Pulp & Paper (PLPR)

Application: SHM-Solids Handling Machinery (SHM)

Substrate: PVC RubberCustomer Location: Pulp mill in Florida U.S.A.

Application Date: June 1998Products:Belzona® 2311 (SR Elastomer)

Problem: The lap joint on a relatively new PVC belt in the finishing area of a chemical cellulose manufacturer had failed. When this system breaks down, the mill is unable to get product through the finishing area and out to customers.

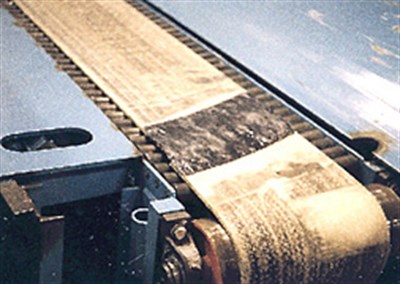

Photograph Descriptions

- Cleaning and degreasing conveyor belt, lacing in place

- Applying Belzona® 2311 (SR Elastomer)

- Finished application with belt in service