BELZONA’S ABS APPROVED PROCEDURE USED TO REPAIR PROPELLER BOLT HOLES

KHIA ID: 337Industry: Marine (MRNE)

Application: SOS-Ships and Offshore Structures (SOS)

Substrate: BronzeCustomer Location: MSTS (Military Sealift Command) in Florida, USA

Application Date: April 1998Products:Belzona® 1111 (Super Metal)

Problem: Excessive pitting on the propeller was due to a combination of crevice corrosion and general corrosion caused vibration and uneven distribution of load.

Photograph Descriptions

- View of military sealift command vessel

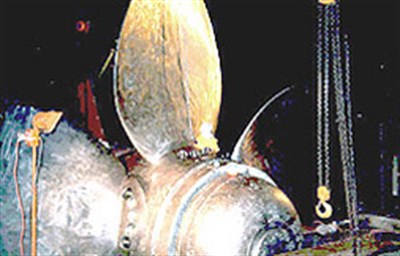

- View of the ships propeller

- Applying Belzona® 1111 (Super Metal) to the bolt holes

- Finished applications being cured