BELZONA REPAIR TO OIL COOLER

KHIA ID: 366Industry: Power (POWR)

Application: HEX-Heat Exchangers (HEX)

Substrate: Copper AlloyCustomer Location: Power Station in Sri Lanka

Application Date: January 2001Products:Belzona® 1111 (Super Metal)

Belzona® 1321 (Ceramic S-Metal)

Problem: The unit was severely damaged and leaking as a result of bimetallic corrosion.

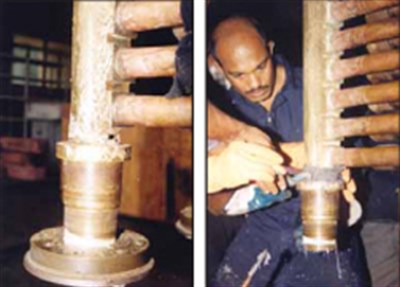

Photograph Descriptions

- Corroded unit with holes clearly visible - Belzona® 1111 being used to repair holed and corroded areas

- Belzona® 1321 being applied to protect unit

- Completed application being pressure tested