BELZONA RAPID ELASTOMER REPAIR TO CHOKE AND KILL HOSE

KHIA ID: 400Industry: Oil & Gas (OILG)

Application: GSS-Gaskets, Seals and Shims (GSS)

Substrate: Rubber liningCustomer Location: Offshore Oil Company

Application Date: February 2001Products:Belzona® 2311 (SR Elastomer)

Problem: Damage had been caused to the rubber on the sealing face of the male hose connector, due to contact with sharp metal edges on the female connector. As a result of this a satisfactory seal was not being obtained and the customer was faced with returning them to the manufacturer for refurbishment.

Photograph Descriptions

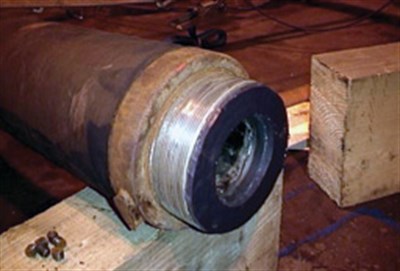

- Damage to the rubber lining on the male connector.

- A new sealing face is produced using Belzona® 2311.

- The hose during pressure testing to 1300 bar.