LOWER HALF OF KNOCK OUT VESSEL PROTECTED WITH BELZONA

KHIA ID: 489Industry: Chemical & Petrochemical (PETR)

Application: TCC-Tanks and Chemical Containment Areas (TCC)

Substrate: SteelCustomer Location: Oil Refinery-Australia

Application Date: May 2004Products:Belzona® 1311 (Ceramic R-Metal)

Belzona® 1391 (Ceramic HT Metal)

Problem: Internal erosion corrosion in lower section caused by sour water. Vessel regularly steamed out.

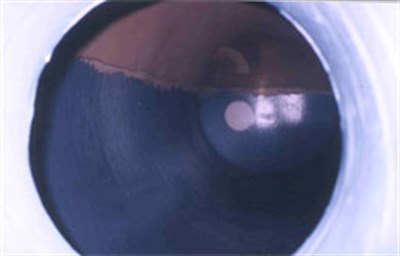

Photograph Descriptions

- Typical limited access to vessel through manway

- Application of Belzona® 1391 underway

- Completed application