BELZONA repairs and protects a heat exchanger against erosion/corrosion

KHIA ID: 5160Industry: Oil & Gas (OILG)

Application: HEX-Heat Exchangers (HEX)

Substrate: Stainless steelCustomer Location: Oil refinery “Ukrtatnafta” in Kremenchug city, Ukraine

Application Date: July 2011Products:Belzona 1311 (Ceramic R-Metal)

Belzona 1391 (Ceramic HT)

Problem: Problems due to high temperatures and erosion caused by particle flow

Photograph Descriptions

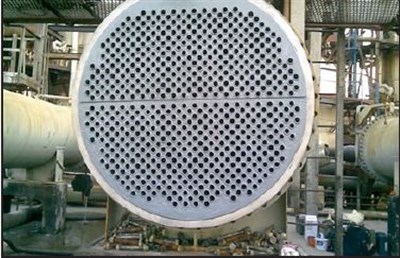

- Erosion/corrosion of the heat exchanger

- Geometry repaired using Belzona 1311

- Repaired surfaces of the heat exchanger after the application of Belzona 1311 and Belzona 1391