BELZONA PROVIDES EMERGENCY REPAIR ON A WORN CONVEYOR BELT

KHIA ID: 5277Industry: General Industry (GIND)

Application: SHM-Solids Handling Machinery (SHM)

Substrate: RubberCustomer Location: BC, Canada

Application Date: September 2005Products:Belzona 2311 (SR Elastomer)

Belzona 2911 (Elastomer QD Conditioner)

Problem: A large hole had formed in this conveyor belt, causing an interruption in production.

Photograph Descriptions

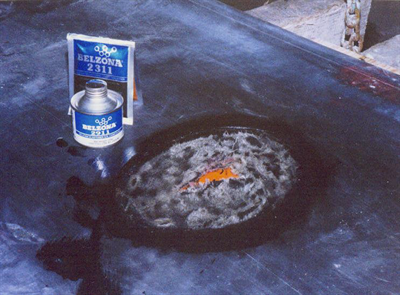

- Damaged conveyor belt, ready for repair.

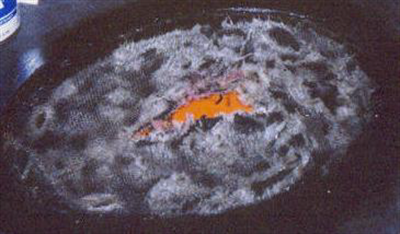

- Close up of repair area showing the use of the Belzona mixing surface, which was positioned underneath the belt to act as a suitable temporary backing for the repair.

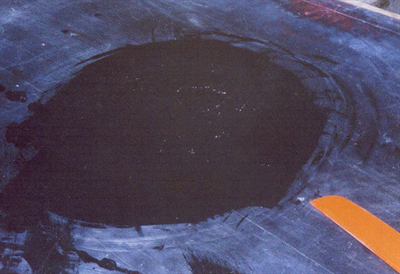

- Completed application.