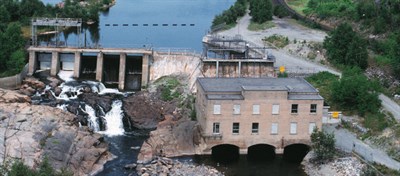

BELZONA REPAIRS TURBINE SHAFT AT A POWER STATION

KHIA ID: 5309Industry: Power (POWR)

Application: CEP-Centrifugal Pumps (CEP)

Substrate: Forged steelCustomer Location: Sudbury, ON, Canada

Application Date: October 2013Products:Belzona 1341 (Supermetalglide)

Belzona 2141 (ACR-Fluid Elastomer)

Belzona 2941 (Elastomer SP-Conditioner)

Problem: Damaged on turbine shaft was caused by cavitation, erosion and corrosion.

Photograph Descriptions

- Power station

- Application in progress

- Completed application

- Application after 6 months