BELZONA REPAIRS PILLOW BLOCK SHAFT

Industry: Pulp & Paper (PLPR)

Application: MPT-Mechanical Power Transmission (MPT)

Substrate: Steel

Customer Location: Idaho, USA

Application Date: 1992

Products:

Belzona 1111 (Super Metal)

Belzona 9411 (Release Agent)

Problem: Seized bearing on 20' shaft. Replacing the shaft would be time consuming, shutting down the entire sawmill for hours.

Photograph Descriptions

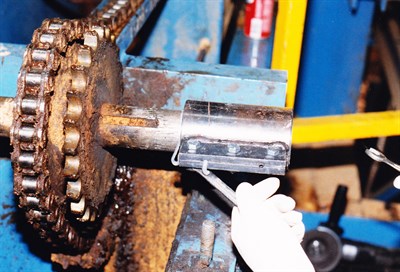

- Applying Belzona 9411 to the former

- Sweating the oil out of the steel shaft using a torch

- Bolting the former in place

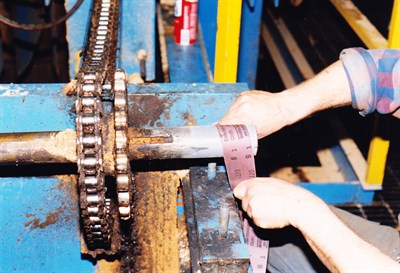

- Dressing down Belzona 1111 with emery cloth

Application Situation

Sawmill shaft.

Application Method

A former was made at the in-house machine shop in accordance with a modified version of Belzona Know-How System Leaflet MPT-2. Note the relief grooves down the side of the flanges. The former received two coats of Belzona 9411, then Belzona 1111 was applied. The shaft was ground and Belzona 1111 was applied. The former was bolted in place and Belzona 1111 was allowed to cure. After 2 hours, the former was removed, the excess of Belzona 1111 was dressed down with emery cloth and the new bearing installed.

Belzona Facts

The former will be used many times as there are hundreds of shafts of the same size in the mill. The whole operation takes less than 3 hours, considerably reducing downtime versus shaft replacement.