BELZONA REPAIRS HYDRAULIC TANK

Industry: Mining & Quarrying (MINQ)

Application: TCC-Tanks and Chemical Containment Areas (TCC)

Substrate: Steel

Customer Location: Covington, VA, USA

Application Date: August 2014

Products:

Belzona 1111 (Super Metal)

Problem: Mounting bolt on the hydraulic tank of a front loader came loose and was leaking.

Photograph Descriptions

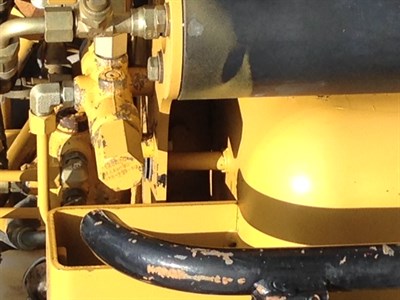

- Overview of the mounting bolt and stud

- Close up of the problem area

- Repair completed

Application Situation

Leaking and loose mounting bolt on front loader's hydraulic tank.

Application Method

The grating around the tank was removed. The area around the mounting stud was then ground and roughened. A detergent was then used to clean the surface, followed by a suitable cleaner/degreaser to remove contaminants such as oil, dirt and grease. Belzona 1111 was then mixed and applied, building up the area around the mounting stud.

Belzona Facts

The Belzona repair to the hydraulic tank saved a great amount of downtime and man hours. Replacement would take the company a day to remove the tank and take it apart. An additional day would be needed to clean, weld and re-assemble. The repair with Belzona took about a half hour, with an additional couple of hours to allow to cure. The front loader was returned to service the following day, since the application was carried out late afternoon. It has been in operation since the repair, with no leaks.