BELZONA CRUISE SHIP CENTRIFUGAL PUMP

KHIA ID: 56Industry: Marine (MRNE)

Application: CEP-Centrifugal Pumps (CEP)

Substrate: BronzeCustomer Location: Italian Cruise Ship in a Southern California Shipyard, U.S.A.

Application Date: December 1996Products:Belzona® 1311 (Ceramic R-Metal)

Belzona® 9411 (Release Agent)

Problem: Severe erosion/corrosion damage, evidenced by more than a dozen small holes, and one large hole completely through the casing as well as a loss of up to two inches of the cutwater. The wear ring seats were also eroded in the same area.

Photograph Descriptions

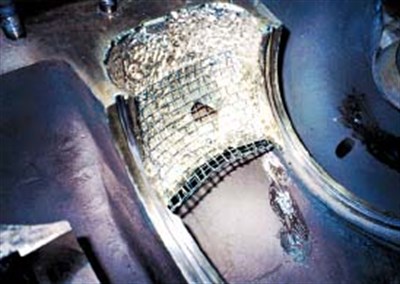

- The pump casing and cutwater after blasting and fitting with expanded metal mesh. Note the hole at the center of the cutwater.

- Belzona® 1311 (Ceramic R-Metal) being pressed through the mesh and into the surface profile of the bronze.

- The finished application. Repaired cutwater edge and casing holes. The seal area and rebuilt seating groove is on the right.