BELZONA IMPROVES EFFICIENCY OF A FIRE TRUCK

Industry: Transport (TRAN)

Application: CEP-Centrifugal Pumps (CEP)

Substrate: Cast iron

Customer Location: Northeastern Washington, USA

Application Date: July 2015

Products:

Belzona 1311 (Ceramic R-Metal)

Belzona 1341 (Supermetalglide)

Problem: Cavitation on the cut-water in the pump.

Photograph Descriptions

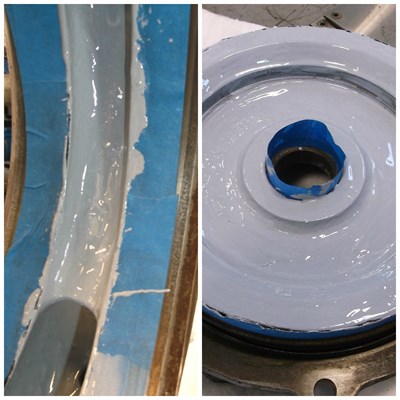

- Cavitation damage / Repaired cavitation damage

- Coated cut-water / Coated end plate

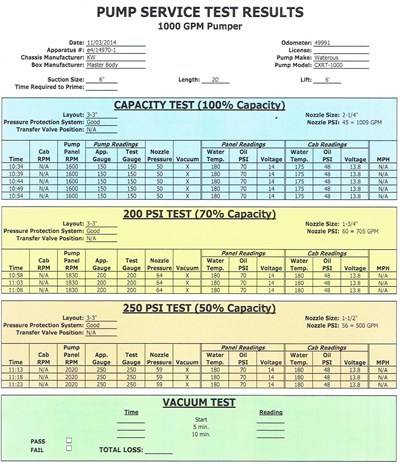

- Pre testing from the first pump showing 1750 rpm

- Post testing from the first pump showing 1600 rpm

Application Situation

Suction pump on a fire truck.

Application Method

The application was carried out in accordance with Belzona Know-How System Leaflets CEP-1 and CEP-3. The surface was grit blasted for preparation and Belzona 1311 applied to repair the cavitation damage, then Belzona 1341 was applied for protection and improved efficiency.

Belzona Facts

The alternative was to purchase a new pump for several thousand dollars. This pump was repaired and coated with US$550 worth of material. This is the second pump this fire department has repaired and coated. These pumps pump 1000 gpm. Prior to coating the pump ran at 1750 rpm to pump 1000 gpm. After coating, the pump only runs at 1600 rpm to pump 1000 gpm.