BELZONA OFFERS PROTECTION TO METAL WEAR PLATES

KHIA ID: 5818Industry: General Industry (GIND)

Application: SHM-Solids Handling Machinery (SHM)

Substrate: SteelCustomer Location: Arthur, ON, Canada

Application Date: March 2015Products:Belzona 1111 (Super Metal)

Belzona 2111 (D & A Hi-Build Elastomer)

Belzona 9811 (Alumina Tiles)

Problem: The wear plates were constantly eroded by the blast media and only lasted weeks in service before being replaced. A big problem arose when the replacement plates became delayed in production and therefore unavailable.

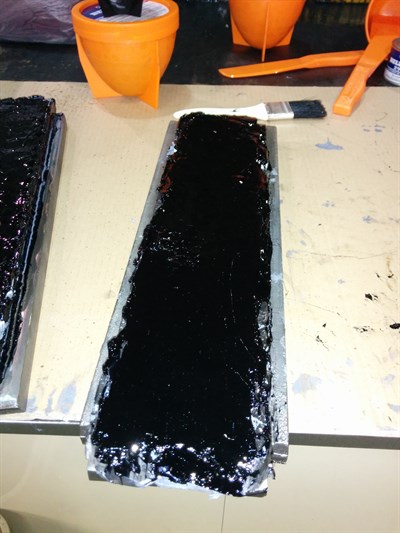

Photograph Descriptions

- Prior to application

- Preparation in progress

- Preparation in progress

- Completed application