FGD AGITATOR BLADE REPAIR IS NO PROBLEM FOR BELZONA 2111

KHIA ID: 5844Industry: Power (POWR)

Application: FBC-Fans, Blowers and Compressors (FBC)

Substrate: SteelCustomer Location: Power Plant, Illinois, USA

Application Date: Fall 2014Products:Belzona 2911 (Elastomer QD Conditioner)

Belzona 2111 (D & A Hi-Build Elastomer)

Problem: Old blades were starting to delaminate and the rubber was holed through and fatigued

Photograph Descriptions

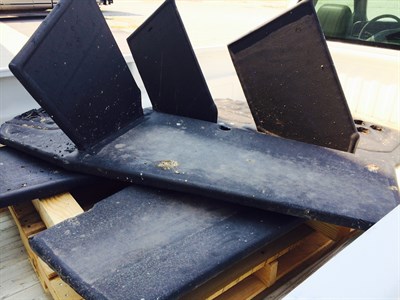

- Old blades

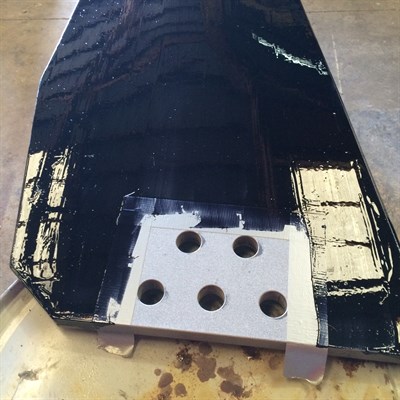

- Blades with 1st coat of Belzona 2111

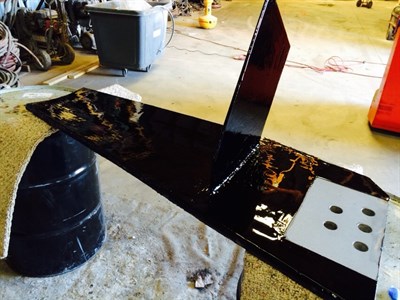

- Thickness being achieved

- Finished product with holes being uncoated so that Belzona 2111 could be applied to the bolts after they were installed