BELZONA SUPERWRAP II MEETS GAS PIPELINE OPERATOR REQUIREMENTS

KHIA ID: 5954Industry: Oil & Gas (OILG)

Application: SOS-Ships and Offshore Structures (SOS)

Substrate: Carbon SteelCustomer Location: Gulf of Mexico

Application Date: October 2015Products:Belzona 9611 (ES-Metal) - (previously named 1291)

Belzona 1161 (Super UW-Metal)

Belzona 1982 (SuperWrap II)

Belzona 9381 (Reinforcement Sheet)

Belzona 9382 (Release Film)

Belzona 9111 (Cleaner Degreaser)

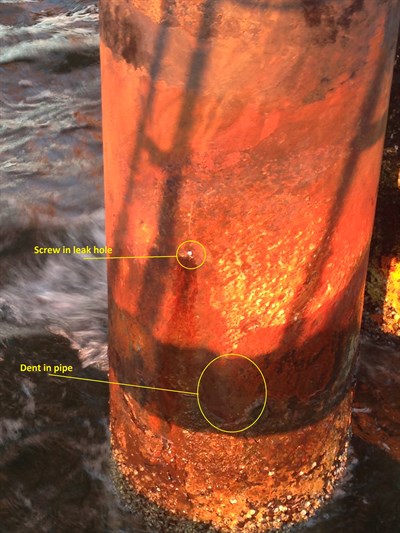

Problem: External corrosion led to a through-wall defect causing the platform to be termporarily shut down. The operator required a permanent repair compliant with DOT Standards. Traditional repairs required fabrication, causing extended downtime and production loss.

Photograph Descriptions

- Riser with defects indicated.

- Belzona 1291 plug and surface profile after blast.

- Skim coat of Belzona 1161 for pit filling and leveling surface.

- Completed SuperWrap II application, 4 wrap (8 layers) system.