BELZONA PROTECTS HOG FUEL SCREW CONVEYOR

KHIA ID: 6009Industry: Pulp & Paper (PLPR)

Application: SHM-Solids Handling Machinery (SHM)

Substrate: Carbon SteelCustomer Location: Montana, USA

Application Date: 2004Products:Belzona 9111 (Cleaner Degreaser)

Belzona 1812 (Ceramic Carbide FP)

Problem: The worn auger would be replaced periodically due to the flights being too thin. The manufacture and replacement of these augers were expensive. The life of the auger was hard to predict due to the varying raw material supplied and the changing demand. Downtime was not a good option when supplying the critical nature of the Boilers.

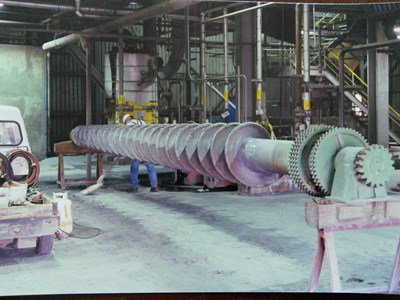

Photograph Descriptions

- Grit Blasting of auger

- Belzona 1812 applied to base of flighting

- Shipping wrap placed over Belzona 1812 to smooth surface

- Full length of auger protected and improved