HEAT EXCHANGER RELIABLY REFURBISHED WITH BELZONA

KHIA ID: 6074Industry: Chemical & Petrochemical (PETR)

Application: HEX-Heat Exchangers (HEX)

Substrate: Carbon SteelCustomer Location: Petrochemical Plant, Teesside, UK

Application Date: 2009Products:Belzona 1511 (Super HT Metal)

Belzona 1391 (Ceramic HT)

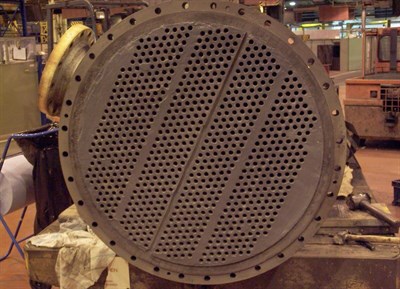

Problem: This Propylene heat exchanger operates at up to 120°C and the tube face had suffered severe galvanic and pitting corrosion. The separator channels and tube face had to be completely rebuilt to prevent bypass of the separator plate. In addition, the client required a lining to prevent further attack to the water boxes, nozzles and the tube faces.

Photograph Descriptions

- Heat exchanger arriving in workshop

- Pitting damage clearly visible after grit blasting

- Tube face being rebuilt

- Belzona application completed