BELZONA ICE MAKER DRUM

KHIA ID: 61Industry: Power (POWR)

Application: TCC-Tanks and Chemical Containment Areas (TCC)

Substrate: Rubber and metalCustomer Location: Nuclear Power Plant in Tennessee

Application Date: 1994Products:Belzona® 2221 (MP Fluid)

Problem: Over time rubber is worn. Ethylene glycol leaks from drum through worn joints and prevents freezing of water and production of ice.

Photograph Descriptions

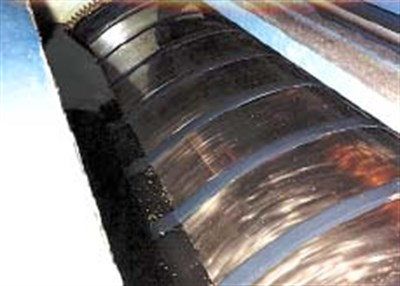

- Ice maker drum with worn rubber coated seals leaking glycol.

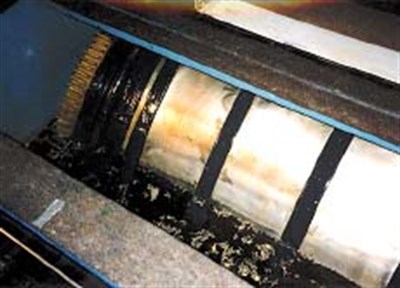

- Duct tape used for a neat repair and Belzona® 2221 applied.

- The finished application; replacement cost saved.