BELZONA KEEPS WHEAT REFINER RUNNING

Industry: General Industry (GIND)

Application: CEP-Centrifugal Pumps (CEP)

Substrate: Steel

Customer Location: Wheat mill in Macedonia

Application Date: December 2000

Products:

Belzona® 1221 (Super E-Metal)

Problem: Bearing failure damaged the shaft.

Photograph Descriptions

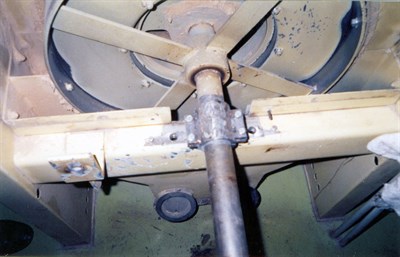

- The damage on the shaft is evident

- The former was used to rebuild the shaft

- The former was removed after Belzona® 1221 had cured

- Bearing re-assembled

Application Situation

Drive shaft on Wheat refiner

Application Method

Application was carried out in accordance with Belzona Know-How System Leaflet MPT-2. Two part mold was prepared before-hand to restore correct shaft diameter.

Belzona Facts

The application was done in few hours. Conventional welding method could cause deformation. Delivery time of a new shaft was 4-6 weeks. New shaft costs 3,700 EUR. All work was finished for 150 EUR. This application was done twice. The shaft still running today.