BELZONA BONDS BEARING PADS ON TIDAL TURBINE

Industry: Power (POWR)

Application: VPF-Valves, Pipes and Fittings (VPF)

Substrate: Steel and Orkot composite bearing pads

Customer Location: Tidal energy developer, Inverness, Scotland

Application Date: August 2016

Products:

Belzona 1121 (Super XL-Metal)

Belzona 1321 (Ceramic S-Metal)

Problem: As a part of the turbine’s composition, the installation of bearing pads was necessary to avoid friction and wear between the Stab and the bearing. The client required a solution to successfully secure the bearing pads into place, which could also endure the compressive and shearing stresses featured during installation and service.

Photograph Descriptions

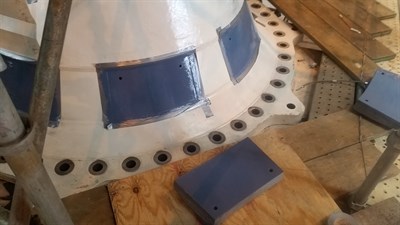

1. The stab prior to application of bearing pads

2. Wetting out the area

3. Application of Belzona 1321 on to bearing pads

4. Bearing pads bonded in place with bolt holes filled

Application Situation

New design for a sub-sea turbine being produced.

Application Method

Application was carried out in accordance with a modified version of Belzona System Leaflet VPF-15. The areas to be bonded were fully grit blasted and degreased in accordance with Belzona surface preparation protocols beforel the bearing pads were bonded into position using Belzona 1321, These were accurately located using screws and keyways. Subsequently, the bolt holes were filled using Belzona 1121, adding further protection.

Belzona Facts

Initially directed toward an alternative bonding material, the bearing pad manufacturer, Orkot, recommended Belzona based on earlier successful projects where "excellent technical support" had been received. Located 30-40 metres below sea level and with infrequent inspection and maintenance over a twenty five year installed life a long term bond is required. During an investigative diving procedure in May 2017, it was revealed that these were in excellent condition and the company has since quoted for other Belzona applications with newly fabricated equipment.