Belzona 4111 Repairs Shell and Secures Wedge Liners in a Ball Mill

KHIA ID: 7732Industry: Steel & Metal Processing (STEL)

Application: TCC-Tanks and Chemical Containment Areas (TCC)

Substrate: Shell and LinerCustomer Location: Metal producer, Mykolaiv, Ukraine

Application Date: 2016Products:Belzona 4111 (Magma-Quartz)

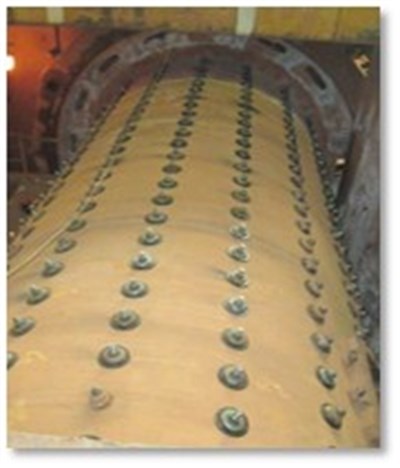

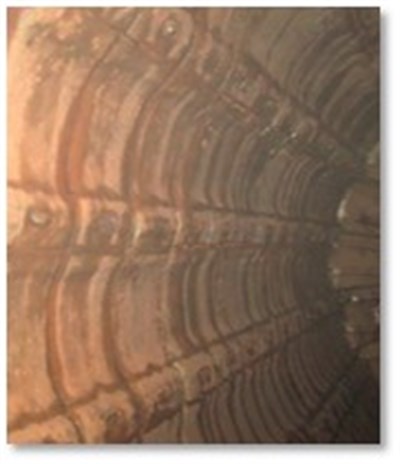

Problem: The wedge liners did not fit together perfectly. Overtime, they caused damage to and distorted the ball mill shell underneath. The refinery wanted to repair the damage and secure the wedge liners. The environment included bauxite and an alkaline solution at 80°C (176°F).

Photograph Descriptions

1. Ball mill, outer view 2. Ball mill, inner view 3. Shell repaired 4. Wedge liner secured