BELZONA RECLAIMS RUBBER LINING OF WATER FILTER IN STEAM GENERATOR

KHIA ID: 78Industry: General Industry (GIND)

Application: TCC-Tanks and Chemical Containment Areas (TCC)

Substrate: Rubber, Stainless SteelCustomer Location: Steam Generating Plant in Venezuela

Application Date: February 1996Products:Belzona® 2111(D & A Hi-Build Elastomer)

Belzona® 2131(D & A Fluid Elastomer)

Belzona® 1311(Ceramic R-Metal)

Belzona® 1321(Ceramic S-Metal)

Belzona® 1211(E-Metal)

Problem: The original rubber lining was cracked, particularly at the points where it was anchored to the substrate. As a result the filter leaked and lost efficiency.

Photograph Descriptions

- External view of water filter

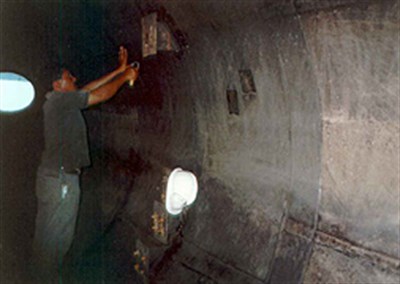

- Preparing the surface of the rubber lining

- Flange faces repaired