Underwater Exhaust Repaired on a 230' Super Yacht

Industry: ()

Application: ()

Substrate: Steel

Customer Location: Florida, USA

Application Date: November 2018

Products:

Belzona 1511 (Super HT-Metal)

Belzona 1391T

Problem: Elbow metal pitting and thinning. Heat from the exhausts gets to 70C.

Photograph Descriptions

From the engine room view of the top of the underwater exhaust

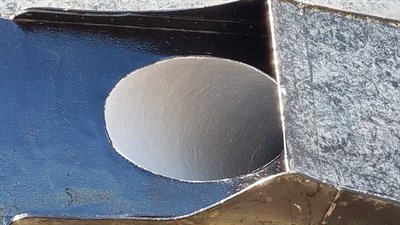

Damage of the underwater exhaust

Application of Belzona 1511 to various damaged areas inside the exhaust

Final coat of Belzona 1391T grey

Application Situation

Elbow of a 7'L x 19"D underwater starboard exhaust for the main engines.

Application Method

The application was carried out in sccordance with modified versions of Belzona Know-How System Leaflets SOS-1 and SOS-2. The surface was prepared by abrasive blast cleaning. A containment was created on both ends of the exhaust to protect the engine room and to protect the exposed blasted steel from the outside elements. The surface was blast cleaned to a near white metal finish to achieve a 3 mill angular profile to apply the Belzona protective system. Belzona 1511 was used to rebuild damaged surfaces, and Belzona 1391T was applied to add protection.

Belzona Facts

The 230' custom super yacht was in a dry dock for its annual maintenance. The ship will have its 20 year inspection and overhaul in 2020 at which time both underwater exhausts will be removed and replaced with new ones. The current inspection showed signs of wear on the exhaust elbow of the steel substrate. The alternative solution was a costly procedure of removing the underwater exhaust and replacing it with a new one. The Customer saved on downtime and repair costs.