Belzona Superwrap II saves FPSO

Industry: Oil & Gas (OILG)

Application: VPF-Valves, Pipes and Fittings (VPF)

Substrate: Carbon Steel

Customer Location: Ivory Coast

Application Date: May 2019

Products:

Belzona 1121 (XL-Metal)

Belzona 1982 (SuperWrap II)

Problem: Corroded flange and fasteners on the High Pressure Fuel Gas Heater inlet and outlet. The operating pressure of the heater is 24 bar at 30°C on the inlet and 36°C on the outlet. Client could not afford for the flange or bolts to leak and be shutdown as would be very costly to them. The client required protection of the system for 9 months until the next shutdown, where the entire unit would be replaced.

Photograph Descriptions

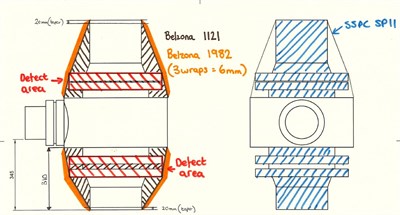

1. Condition of Flanges and valve 2. Design output 3. During application of Inlet 4. Finished application

Application Situation

From the initial inquiry up to the installation of the Belzona Superwrap system was handled by a Belzona Engineer. A design was created at Belzona HQ for the local distributor. The local distributor didnt have any trained validated Belzona Superwrap II Installers so arrangements were made for the Belzona engineer to travel on behalf of the distributor and carry out the application. On arrival onto the FPSO and checking the valve in question a gearbox was missed off the initial design and a new design had to be completed on site. After a re-design and confirmation from Belzona HQ the job commenced the following day. Timing were critcial as the temperatures were close to the maximum allowed for the product.

Application Method

The application was carried out by validated Superwrap Installers as per the Belzona Superwrap II method statement provided on the design. Following thorough surface preparation to SSPC-11 to the live system, Belzona 1121 was applied to the flanges, bolts and pipe to create a and a smooth transition onto the pipe. The Belzona Superwrap II system was then applied. Due to the air and steel temperature the repair required consolidating in Belzona 9382 Release Film after each wrap. Upon reaching the required thickness of 6 mm the wrap was allowed to cure. Once cured the Belzona 9382 release film was removed. This application was completed in accordance with Belzona System Leaflet VPF-11.

Belzona Facts

Following the initial inquiry and application of the Belzona Superwrap system, the Belzona engineer performed validated Installer and Supervisor training for the local distributor as they have a good relationship with the client and would be more cost effective for the client to have an local applicator.