Belzona Batch Mixer Lining

KHIA ID: 8089Industry: Food & Drink (FOOD)

Application: VPF-Valves, Pipes and Fittings (VPF)

Substrate: SteelCustomer Location: Flintshire, United Kingdom

Application Date: February 2019Products:Belzona 1321 (Ceramic S-Metal)

Problem: Previously Belzona completed corrosion and pitting repairs on some batch mixers for this customer. They fabricated a new mixer, and wanted to prepare for any corrosion and pitting in the future which is intensified by the production of Chloride during the mixing process, by lining the mixer with Belzona products.

Photograph Descriptions

1. The vessel being transported into the Belzona Technosol workshop, ready for work to begin.

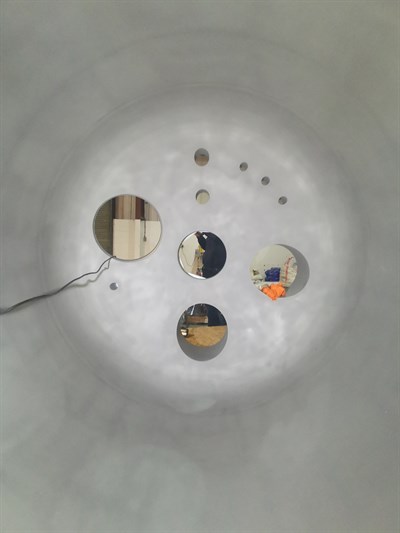

2. The inside of the vessel before being cleaned and blasted, ready for the coating.

3. The first coating of Belzona 1321 Grey

4. The finished application, after the second coating of Belzona 1321 Blue.