Belzona 5892 Repairs a Tank in Brewery

Industry: Food & Drink (FOOD)

Application: TCC-Tanks and Chemical Containment Areas (TCC)

Substrate: Steel

Customer Location: Poland

Application Date: 2019

Products:

Belzona 1111 (Super-Metal)

Belzona 5892

Belzona 9341 (Reinforcement Sheet)

Problem: The tank in the brewery was suffering from pitting corrosion of the welds, stub pipes and general corrosion of the internal metal sheets.

Photograph Descriptions

- Brewery Tank

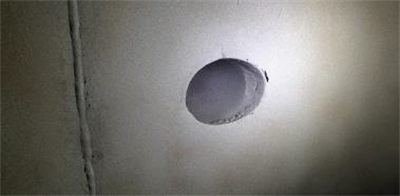

- Pitting Corrosion on the joints inside the tank.

- Re profiling joints with Belzona 1111

- Appplication of the Belzona 5892

Application Situation

A brewery tank containing a beer solution required an product to repair pitting and an internal lining to prevent further corrosion & maintain hygienic conditions within the tank.

Application Method

Started out with grit blasting to prepare the surface. This was then followed by repairing the welds with Belzona 1111. The repairs of the connectors with Belzona 9341 used in conjunction with Belzona 1111. The 1st layer of Belzona 5892 at an average thickness about 250 μm. Application of the 2nd layer Belzona 5892 average thickness about 250 μm. Finally a thickness test was carried in line with the Belzona 5892 IFU. The application was carried out in acordance with Belzona System Leaflet TCC-03.

Belzona Facts

The client chose Belzona due to it's product quality and little down time. The Belzona 5892 was a great choice due to it's ability work under immersed conditions at a competitive cost.