Belzona® Provides Corrosion Protection for Hydrochloric acid Chemical Tank Lining

Industry: Chemical & Petrochemical (PETR)

Application: TCC-Tanks and Chemical Containment Areas (TCC)

Substrate: Carbon steel

Customer Location: Petroleum Company in Guangdong, China

Application Date: July 2014

Products:

Belzona 4341 (Magma CR4)

Belzona 1111 (Super Metal)

Problem: The chemical tank lining has experienced chemical corrosion, which could lead to safety hazards.

Photograph Descriptions

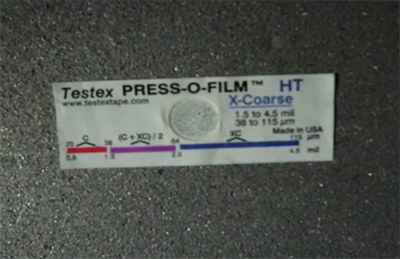

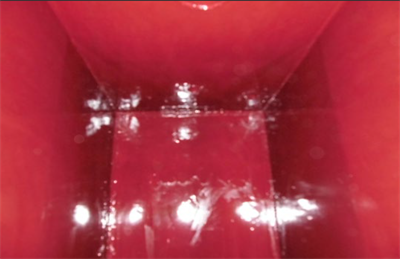

1. Corrosion situation of metal surface; 2. Measure roughness of blasted metal surface; 3. Measure thickness; 4. Tank lining repaired

Application Situation

hydrochloric acid chemical tank

Application Method

Application carried out in accordance with Belzona Know-How System Leaflet TCC-5. Blast clean corrosion spots on the tank lining to achieve a minimum depth profile of 3 to 4 mils. Clean the prepared metal surface with Belzona 9111 and wait till dry. Then rebuild lost metal surface with Belzona 1111 before applying Belzona 4341. After first layer touch dries (within 24hours), apply the second layer. Last but not least, measure coating thickness of a chosen area by using a thickness gauge to make sure the thickness no less than 500μm.

Belzona Facts

Belzona 4341(Magma CR4) is a two-component barrier coating for protecting surfaces subject to chemical attack. It is optimised for resistance of inorganic acids. This high-performance coating protects tank lining, saved the client's cost of replacing equipment and eliminated potential safety hazards. The Client is very satisfied with Belzona solution.