Tube sheet engine cooling exchanger protection with Belzona

Industry: Power (POWR)

Application: HEX-Heat Exchangers (HEX)

Substrate: Steel

Customer Location: Nuclear electric power plant in Slovakia.

Application Date: 2018, 2019, 2020

Products:

Belzona 1111 (super metal)

Belzona 4311 (Magma CR1)

Problem: These strong acids even if they are diluted cause big corrosion.

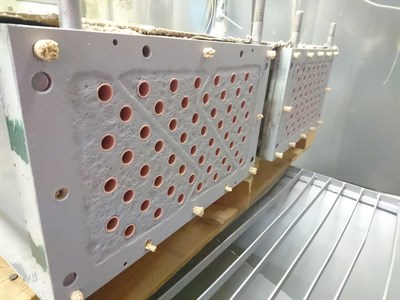

Photograph Descriptions

- Strong acids even if they are diluted cause big corrosion

- The substrate was grit blasted and cleaned with Belzona 9111

- Tube sheets are levelled on the milling machine

- The application was then protected by 2 coats of Belzona 4311

Application Situation

The nuclear electric power plant needs to cool some engines by these exchangers (water - inlet 33°C outlet 50°C / air - inlet 110 °C). They have problems after cleaning process, because they use cleaners which content formic, phosphoric and hydrofluoric acids.

Application Method

The application was carried out in accordance with Belzona System Leaflet HEX-01. The substrate was grit blasted and cleaned with Belzona 9111. Then all the holes on tube sheets were plugged with corks. The corks were then cut at the tube level and Belzona 1111 (super metal) was used to rebuild the substrate. Tube sheets are levelled on the milling machine after that. The application was then protected by 2 coats of Belzona 4311 (magma CR1). The corks are taken off with a drill. The tubes were then cleaned with compressed air.

Belzona Facts

This customer needed some supplier, which is able to make these repairs in short and guaranteed time also in perfect quality with high resistant coating. After the reassembling they required the pressure test with 8 bars water. Because Belzona 4311 (magma CR1) needs for completion of the molecular reaction with full chemical resistance 7 days in 20°C (but customer wants to get back these exchanger in 5 days), we had to use force curing 80°C in 4 hours.