BELZONA 5871 PROTECTS STEAM PIPING HAZARDOUS TO OPERATORS

Industry: Pulp & Paper (PLPR)

Application: VPF-Valves, Pipes and Fittings (VPF)

Substrate: Steel

Customer Location: Alabama, USA

Application Date: May, 2020

Problem: These piping sections were a potential hazard for contact burn injuries since they are located at ground level.

Photograph Descriptions

- Pipe coated with Belzona 5871

- Pipe coated with Belzona 5871

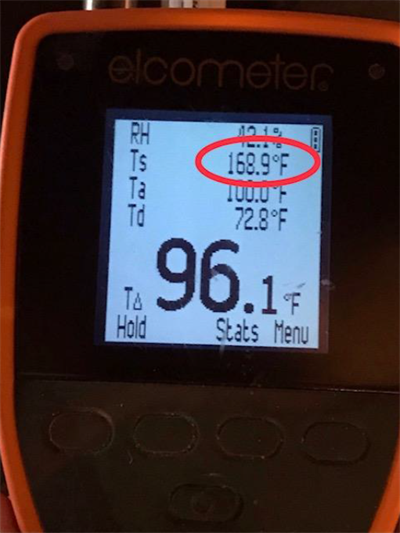

- Measuring temperature after application of Belzona 5871

- Measuring temperature after application of Belzona 5871

Application Situation

Steam piping of four identical sections of a batch digester at a local paper mill, operating at 200°F max.

Application Method

The line was shut down for safety handling during application procedure. Belzona 5871 was applied in 4 coats in one day, with a total DFT of 160-180 mils.

Belzona Facts

The curing time of Belzona 5871 was accelerated becaude the pipe was still warm during application. All 4 layers of Belzona 5871 were applied in one day, and 4 more identical pipe sections were repaired during a planned maintenance. Belzona was able to reduce the temperature down to 110F, preventing any type of contact surface burn and protecting the pipe against future corrosion degradation.