Belzona Lays New Chemical Foundation in Food Sector

KHIA ID: 8365Industry: Food & Drink (FOOD)

Application: FPA-Floor Problem Areas (FPA)

Substrate: ConcreteCustomer Location: Finland

Application Date: August 2020Products:Belzona 4111 (Magma-Quartz)

Belzona 4911 (Magma TX-conditiioner)

Belzona 4154 (Magma Quartz resin)

Belzona 4311 (Magma CR1)

Problem: Downtime was a big factor. Time given for the whole project of dissassemble the old equipment, building new foundation and assembling the new equipment was 5 days. Disassembly took 2.5 days due to some difficulties, and the assembling, including adjustments of the equipment needed 2 days, so the foundation needed to be ready for assembling on Thursday morning. Time given for preparing, building and top-coating was finally only from Wednesday 15:00 to Thursday morning 07:00. During this time also the Top-Coat needed to be ready for light loading and light pedestrian footfall.

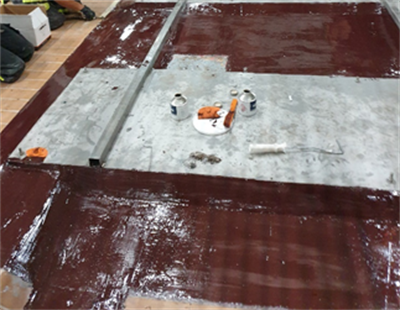

Photograph Descriptions

Picture 1 : Old floor de-assembly

Picture 2 : Deeper areas (2-30cm) filled with Belzona 4154

Picture 3 : Belzona 4111 used to reach the final level

Picture 4 : Belzona 4311 used as a top-coat , a final chemical resistant and safe floor-surface is achieved.