Belzona Restores Concrete Settlement Tank Walls

KHIA ID: 8411Industry: Water / Wastewater (WATR)

Application: TCC-Tanks and Chemical Containment Areas (TCC)

Substrate: ConcreteCustomer Location: Lancashire, UK

Application Date: October 2020Products:Belzona 4131 (Magma-Screed)

Belzona 2211 (MP High-Build Elastomer)

Problem: The top of the concrete walls of multiple FST's had suffered from abrasive wear due to the action of the wheels that drive the rotating separator arms. This has been further aggravated by freeze-thaw cycles on the damaged and damp concrete substrate. There has also been damage to expansion joints, which have been repaired previously, but began showing signs of failure.

Photograph Descriptions

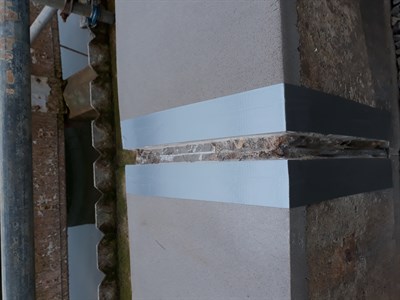

1 - Expansion joint before repair

2 - Expansion joint after repair

3 - Belzona 4131 during application

4 - Repair completed

Application Situation

A waste water treatment plant had noticed increasingly severe damage to the walls of multiple Final Settlement Tanks (FST). The walls themselves were deformed and damaged in various locations, and the top of the walls had suffered from abrasion.Application Method

Belzona 4131 was applied to the top of the walls to create a hard, compression and abrasion resistant surface to provide long term protection and prolong its service life. The expansion joints were removed and replaced with Belzona 2211 to allow for the expansion/contraction of the concrete. The work was completed in accordance with Belzona System Leaflets TCC-09, TCC-11 & TCC-12.Belzona Facts

The customer was seeking a long-term, fast alternative to replacement so that the FST's could be used for many years to come.Belzona 4131 provided better abrasion protection than the original concrete substrate, and Belzona 2211 gives flexibility and very high adhesion to the surrounding material.