Belzona Provides Cold Bonding Solution to Storage Tank

Industry: ()

Application: ()

Substrate: Glass Fused Steel

Customer Location: Dublin, Ireland

Application Date: 2020

Products:

Belzona 1111 (Super Metal)

Belzona 5811 (Immersion Grade)

Problem: A crisp factory located in Dublin, Ireland, had suffered from corrosion within a storage tank containing process wastewater. Over time, the glass fused steel resulted in multiple through-wall defect areas on the substrate surface, which if left untreated, could have produced a serious problem with environmental and economic impacts. The Customer was in need of a quick, yet simple solution that ultimately ruled out the need for replacement and one that would have minimal impact on production.

Photograph Descriptions

1. Damage to the surface

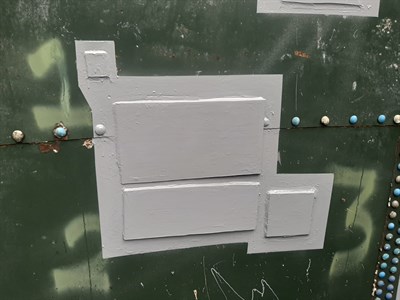

2. Surface preparation and plate bond using Belzona 1111

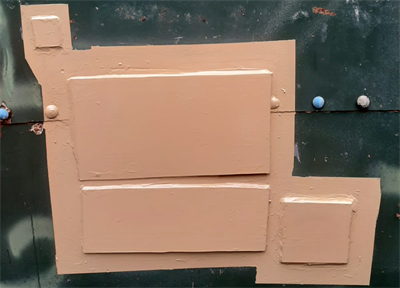

3. First coat of Belzona 5811

4. Second coat of Belzona 5811

Application Situation

Glass fused steel storage tank suffering from internal corrosion

Application Method

The surface was grit blasted to SA 2.5 before being cleaned and dried, ensuring there was no loose contaminants. Belzona 1111 was used to bond the steel plate to the substrate. The material was applied directly to the surface, as well as the plate, and then bonded to the tanks surface. The plate bond was then allowed to cure before Belzona 5811 could be applied to encapsulate the plate, and to also prevent further corrosion. Once cured, the plate itself as well as around the edges were grit blasted. A first coat of Belzona 5811 was then brush applied over and around the plate. A second coat was then applied later to complete the solution.

Belzona Facts

Beltech Industrial Limited, Belzona’s Distributor in Ireland, was able to present the ideal solution to the Customer. This solution would eliminate the need for traditional methods such as welding which can present safety risks, increased downtime, and further defects or failures. The existing tank lining also did not allow for welding. Using a cold-bonding solution completely removes the risk to the internal coating and ensures a fast and simple in-situ application that can even be applied directly over riveted joints as can be seen in the photos, without the need for special equipment.