Belzona Repairs and Protects Francis Turbine

KHIA ID: 8706Industry: Power (POWR)

Application: CEP-Centrifugal Pumps (CEP)

Substrate: Stainless SteelCustomer Location: Hydroelectric Power Plant, Turkey

Application Date: December 2021Products:Belzona 9111 (Cleaner Degreaser)

Belzona 1311 (Ceramic R-Metal)

Belzona 1341 (Supermetalglide)

Belzona 2141 (ACR-Fluid Elastomer)

Belzona 2941 (Elastomer SP-Conditioner)

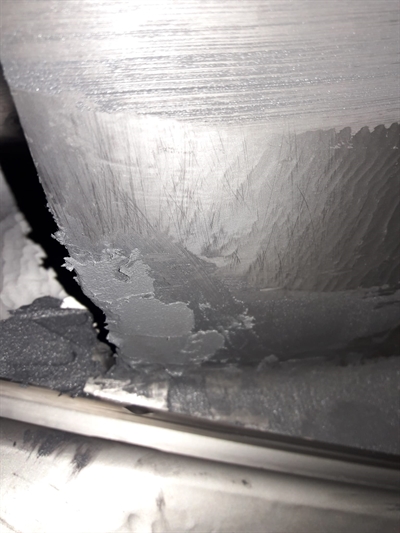

Problem: Over time, the turbine had suffered from serious erosion, cavitiation and several parts of the vanes had deteriorated due to foreign matter entrained within the process. During an inspection, severe pitting was identified in the draft tube area.

Photograph Descriptions

1.) Rebuilt damaged vanes with perforated sheet

2.) Cavitated vane tips repaired with Belzona 1311

3.) 1st coat of Belzona 1341

4.) Final application

Application Situation

Restoration of a 91Mw francis turbine within an Hydroelectric power plant.Application Method

This application was carried out in accordance with modified system leaflets CEP-01, CEP-05 & CEP-10.First, the turbine was grit blasted to SA2.5, achieving a surface profile of 75 microns before being cleaned with Belzona 9111. Once the surface was clean & dry, any severely pitted areas or damaged vanes were rebuilt with Belzona 1311 along with perforated metal sheets, restoring the turbine back to it's orignial dimensions. After the 1311 had cured, the surface was frost blasted (40 microns) before applying 2 coats of Belzona 1341. Finally Belzona 2941 conditoner and Belzona 2941 were applied to the the tips of the turbines vanes as these areas were most suspectible to cavitation.