BELZONA SAVES VITAL CHILLER

Industry: General Industry (GIND)

Application: HEX-Heat Exchangers (HEX)

Substrate: Steel

Customer Location: Soybean Processor, Kansas

Application Date: June 2007

Products: Belzona® 1311 (Ceramic R-Metal)

Belzona® 1321 (Ceramic S-Metal)

Problem: Bi-metallic corrosion was deteriorating the tube sheet surfaces. If the problem was left unresolved, the chiller would eventually suffer servere damage through internal leakage.

Photograph Descriptions

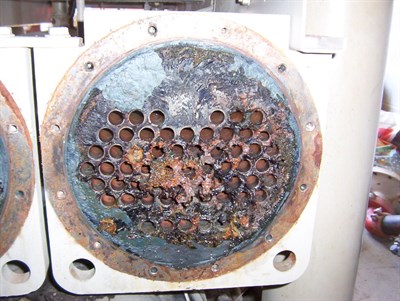

- Original condition of tube sheet with scale build-up

- Bi-metallic corossion damage revealed by blast cleaning. Note the voids between the tubes and tubesheet.

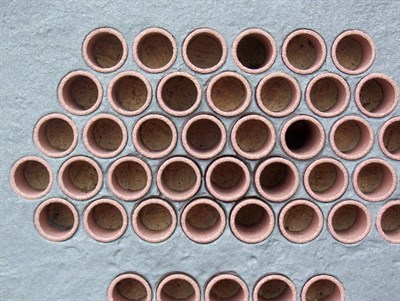

- Tube sheet. The surface was sanded to provide a perfect sealing surface.

- Protected end covers

Application Situation

During the plant turn around it was discovered that an essential chiller was in dire need of repair.

Application Method

Application was carried out in accordance with Belzona System Leaflet HEX-1, 2 & 3. Belzona® 1311 was used to replace the missing metal. Two coats of Belzona® 1321 provides a corrosion barrier to the surfaces. A fine grit grind stone was used to smooth the surface. This allows the use of the OEM Trane o-ring seals.

Belzona Facts

The local Trane dealer called and needed the chiller repaired in a hurry as the plant was in the middle of its one week turn around. The entire chiller and end covers were refurbished to better than new condition in two days and returned to service a couple days later. Not only was the chiller repaired for a fraction of the cost of replacement but it saved the plant from unexpected expensive down time.