BELZONA EXTENDS THE LIFE OF A WATER PUMP

KHIA ID: 5334Industry: Food & Drink (FOOD)

Application: CEP-Centrifugal Pumps (CEP)

Substrate: Cast IronCustomer Location: Washington, USA

Application Date: 1992Products:Belzona 2131 (D & A Fluid Elastomer)

Belzona 1321 (Ceramic S-Metal)

Belzona 4911 (Magma TX Conditioner)

Problem: The pump removes dirty water used to wash potatoes as they enter the processing plant. The entrained dirt wears the pump impeller prematurely.

Photograph Descriptions

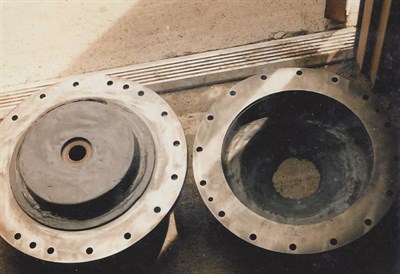

- New impeller blasted and conditioned

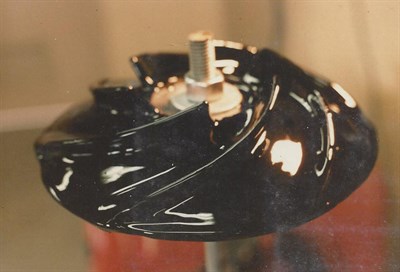

- Impeller coated with Belzona 2131

- Two coats of Belzona 1321 applied to casing