BELZONA PROVIDES THE SOLUTION TO A PUMP PROBLEM

KHIA ID: 6063Industry: Water / Wastewater (WATR)

Application: CEP-Centrifugal Pumps (CEP)

Substrate: Cast IronCustomer Location: Lake Stevens, WA, USA

Application Date: May 2016Products:Belzona 1111 (Super Metal)

Belzona 1321 (Ceramic S-Metal)

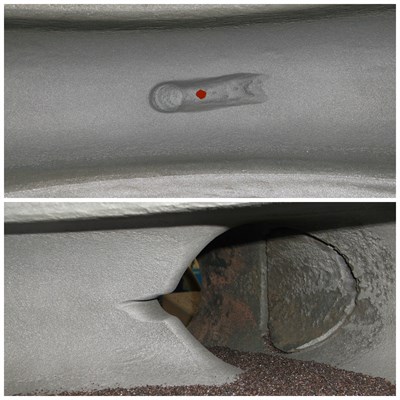

Problem: The pump had a 1/4" hole appear on the outside of the volute, allowing for wastewater to leak during operation. After opening the pump, it was discovered that there was fairly extensive damage in four locations as well as damage to the cutwater and erosion in the throat and on the flange face.

Photograph Descriptions

- Top: Hole in the volute / Bottom: Damage to cutwater.

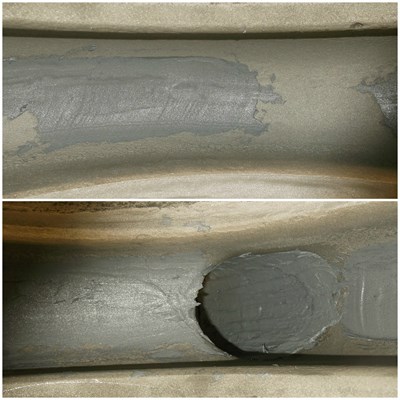

- Top: Hole in volute repaired / Bottom: Damage to cutwater repaired with 1111.

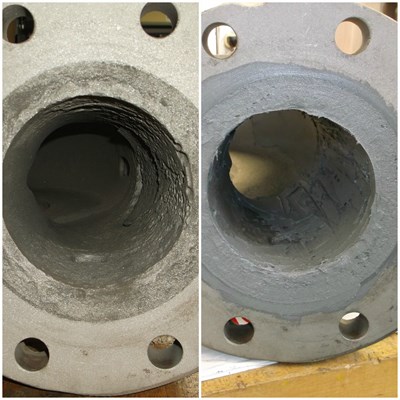

- Flange face damage / Flange face damage repaired.

- Completed application with 1321 overcoat.