BELZONA PROTECTS EVAPORATORS IN DISTILLATION UNIT

KHIA ID: 110Industry: Oil & Gas (OILG)

Application: TCC-Tanks and Chemical Containment Areas (TCC)

Substrate: Stainless steel 317LCustomer Location: National Oil Company

Application Date: May 1996Products:Belzona® 1391

Problem: Floor plate in No. 4 Distillation unit was showing considerable corrosion and weld repairs, including welding in of new plate sections had already been carried out previously.

Photograph Descriptions

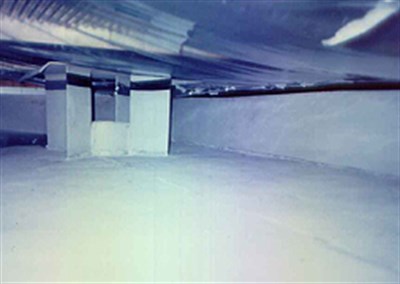

- General view of the 4 Distiller units.

- Work underway inside the Evaporator. Note low temperature lighting used to minimise air temperature.

- Belzona® 1391 applied to base and 30cms up side of all steelwork in unit.